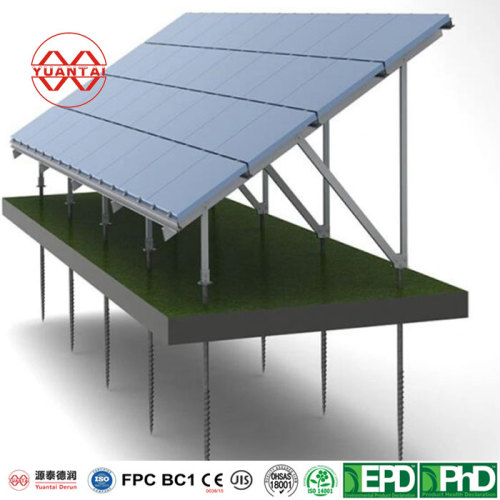

Wholesale production of steel spiral ground pile manufacturer

- Model

- ytdr-1001

Item specifics

- Warranty

- 3years, 10 Years

- Anti-Corrosive

- Hot-dip galvanized

- Material

- Q235B

- Package

- Standard export sea-worthy packing

- Port

- Tianjin xin port

- Payment

- TT/LC

- Delivery time

- 7-30 days

- Certification

- CE

- Installation Site

- all type of soil

Review

Description

The screw ground pile is a screw drill ground pile, which is characterized in that it comprises a drill bit and a drill pipe, and the drill bit or drill pipe is connected with the power source input joint; After the pile is driven underground, it will not be taken out and will be directly used as a pile

The bits described above include the bottom auger bit

1、 Middle steel pipe

2、 Upper connecting pipe

3、 The drill pipe comprises an upper connecting pipe

4、 Middle steel rod

5、 Lower coupling shaft

6、 After being driven underground, the pile here is no longer taken out, but directly used as a pile.

On the basis of "end bearing pile" structure and "friction pile" structure in the construction process, it is more widely used in the construction of a variety of ground piles, ground anchors and randomly constructed ground piles.

Processing technology of spiral ground pile

Generally, qualified ground piles can be produced through cutting, deformation, welding, pickling, hot plating and other technological processes. Pickling and hot galvanizing are important anti-corrosion treatment processes, which directly affect the service life of spiral ground piles.

The processing level of the ground pile directly determines the service life of the metal ground pile, such as the quality of the selected welded pipe, the quality level of welding, whether there are sand holes, false welding and the width of welding, which all affect the future service life of the ground pile and the quality of subsequent processing. Pickling is an important basic anti-corrosion process, and the quality of hot plating, such as the time of hot plating and the quality of surface treatment, All affect the quality of ground pile anti-corrosion treatment. Generally, the spiral ground pile can be used for 40-80 years. The environment and use method of the use process also affect the service life of the ground pile, such as the acid-base degree of the soil, whether the operation process is proper, and improper use will lead to the destruction of the surface of the metal ground pile, the destruction of the metal protective layer, the acceleration of the corrosion of the metal ground pile and the reduction of the service life.

Application knowledge of spiral ground pile

Spiral ground pile is generally used to strengthen tents in sandy land and prevent tents from being blown away by the wind. At the same time, the ground holding capacity of spiral ground pile is better than that of general inclined ground pile in sandy soft soil