How to solve the corrosion problem of galvanized square pipe?

- Share

- From

- www.ytdrintl.com

- publisher

- youyouxiaotian

- Issue Time

- Aug 23,2022

Summary

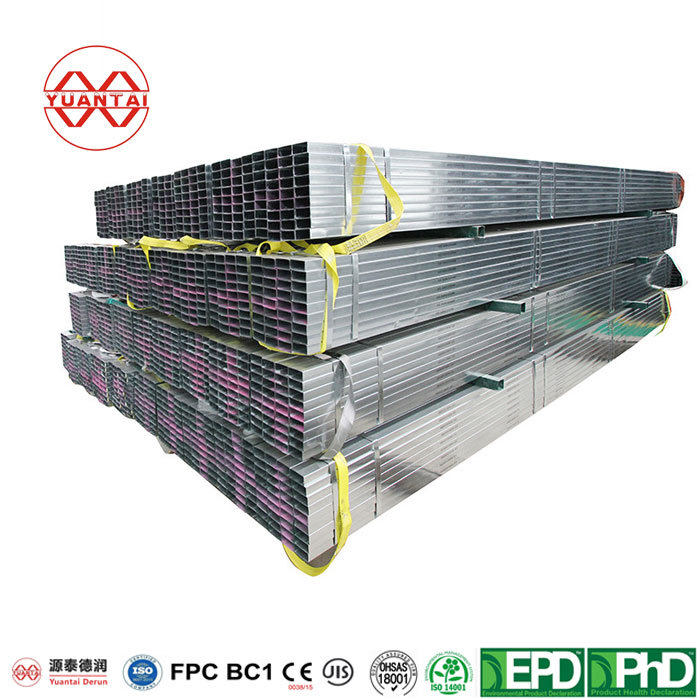

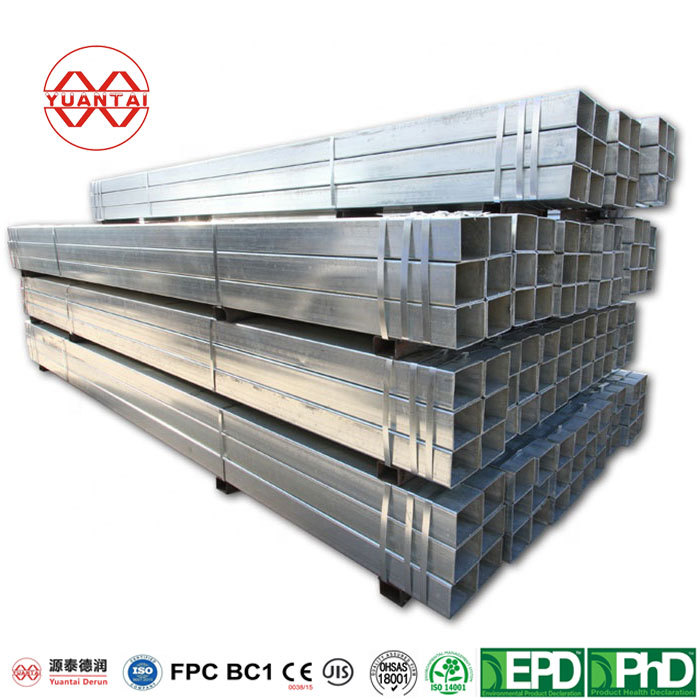

Most square pipes are made of steel tubes, and hot dip galvanized square pipes are made of a special process to attach a layer of zinc to the surface of the steel tubes. Next, we will explain how to solve the corrosion problem of galvanized square pipes in detail.

How to solve the corrosion problem of galvanized square pipe?

Most square pipes are made of steel tubes, and hot dip galvanized square pipes are made of a special process to attach a layer of zinc to the surface of the steel tubes. Next, we will explain how to solve the corrosion problem of galvanized square pipes in detail.

The first step is to knock: in order to make the nut easier to loosen, you need to use a square hammer to slightly knock rusty 304 seamless galvanized square pipe, galvanized square pipe factory reasonable stacking knowledge if it is cast iron nut need to be slightly harder, Q345B galvanized square pipe and general plastic just gently knock. If not, use a hammer to knock 304 seamless galvanized square pipe along the direction.

The second step is a shock: must not use a wrench to screw rusty stainless steel screws, to avoid breaking stainless steel screws or wrench. At this time it is necessary to use a hammer to shake the wrench handle can easily unscrew the rusty stainless steel screws.

The third step: sometimes 304 seamless galvanized square pipe will be deformed due to corrosion, galvanized square pipe - galvanized square pipe - hot dip galvanized square pipe factory - galvanized square pipe factory - Tianjin galvanized square pipe factory can not use a wrench or wire cutters to remove it, then it is necessary to use the "impact method". What is the "impact method"? Is to use the hammer and hammer in the vertical direction of the top of the 304 seamless galvanized square pipe impact out of the "U-shaped groove", galvanized square pipe factory reasonable stacking knowledge and then adjust the Angle of the punching cone, Q345B galvanized square pipe until the oil flow can unscrew the rusty 304 seamless galvanized square pipe.

Step 4: When the 304 seamless galvanized square pipe rust condition is relatively serious, the above methods are all work, must take the form of "fire", now the screw and nut with gas welding oxidizing flame to barbecue, stay on the surface after burn red drops a little oil, adopt the method of "heat bilges cold shrink", make the screw and 304 seamless galvanized square pipe increases, the gap between The rusted 304 seamless galvanized square pipe can be unscrewed until the oil flows in.